Thermomechanical Analyzer TMA7000 Series Model:TMA7100 and TMA7300

High temperature control technology that handles a variety of temperature programs

Available DSC measurement, it makes specific heat capacity measurements available

The sample observation and measurement, Hitachi’s pioneering key feature

Includes the newly designed flow channels for high-level gas exchange

In addition to conventional applications, the NEXTA STA series shows its strength in analyses such as quantitative determination of the constituents of advanced materials, composite materials, and trace amounts of moisture.

-

Features

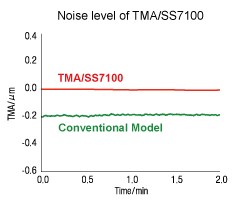

High Sensitivity

TMA7000 is equipped with newly developed “Z-stabilizer” signal optimization technology, which cuts noise levels to achieve highly sensitive measurements.

High-Temperature High-Humidity Measurements

Additional options allow measurement under high temperature and high humidity conditions. Furthermore, it is extensible to swelling and vacuum measurements.

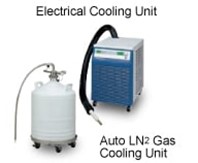

The Eco-Friendly Cooling Unit

The eco-friendly cooling unit cuts liquefied nitrogen consumption by approximately 40% (compared to previous models). Electrical cooling units that do not use liquefied nitrogen can also be connected.

Effective Atmosphere Control

A mass flow meter can be incorporated into the gas control so the atmosphere can be efficiently controlled by not only the purge gas ON/OFF switch but also programmed flow rate control.

Improved Temperature Control Function

The new built-in temperature control function is designed to reduce the gap between the program temperature and the measurement sample temperature and improve temperature compliance.

-

TMA7100 TMA7300 Sample Cylinder Quartz, metal Alumina Temperature Range -170 to 600°C Ambient to 1,500°C TMA Measurement Range ±5 mm Sample Cylinder 0.01 µm Load Range ±5.8 N Scan Rate 0.01 to 100°C/min Maximum Sample Size Expansion; Φ10×L25 mm

Tension; W1×T5×L25 mm

Expansion; Φ10×L25 mm

Sample Length Measurement

Automated Measurement

-

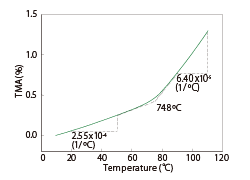

Thermal Expansion of Polyvinyl chloride (PVC)CTE (coefficient of thermal expansion) changes at the glass transition temperature. CTE after Tg is approximately 4 times larger.

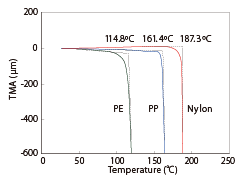

Penetration on Polymer filmComparison of softening temperatures between different polymer films, Polyethylene, Polypropylene and Nylon evaluated by penetration measurement.

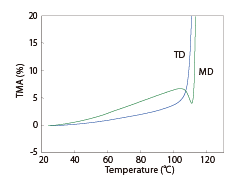

Anisotropy of Polyethylene (PE) filmIn above measurements of PE film, tension force is applied in machine direction (MD) and the transverse direction (TD).

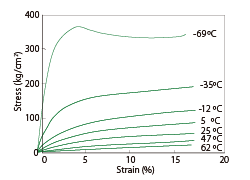

Stress-Strain characteristic of Polyethylene (PE) filmThe measurements are carried out on PE film with strain control mode at different temperature.

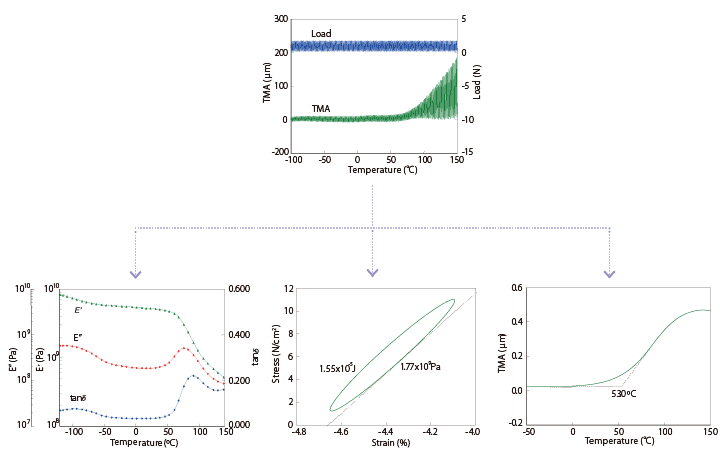

Stress-Strain Capabilities

The TMA 7000 series has stress strain measurement and analysis capability. Stress-Strain characteristic, Creep/Recovery, Stress Relaxation can be measured, and furthermore, applying sinusoidal force to samples the dynamic viscoelastic behavior can be characterized.