Differential Scanning Calorimeter (DSC) NEXTA® DSC series Model:NEXTA DSC600 and DSC200

NEXTA DSC series, Hitachi’s latest series of differential scanning calorimeter (DSC), delivers superior sensitivity with exceptional baseline stability. Moreover, it allows an even wider temperature range for Real View®. NEXTA DSCs also have ability to use temperature modulated DSC method to determine specific heat capacity. Together with the enhanced safety features designed in make this instrument even more user-friendly.

The series of DSCs provide cutting-edge measurement technology for quality control in various fields as well as research and development of polymers, inorganic materials, pharmaceuticals, and others.

The series of DSCs provide cutting-edge measurement technology for quality control in various fields as well as research and development of polymers, inorganic materials, pharmaceuticals, and others.

-

Features

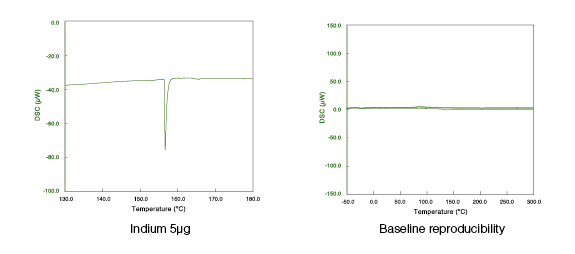

World-class baseline repeatability

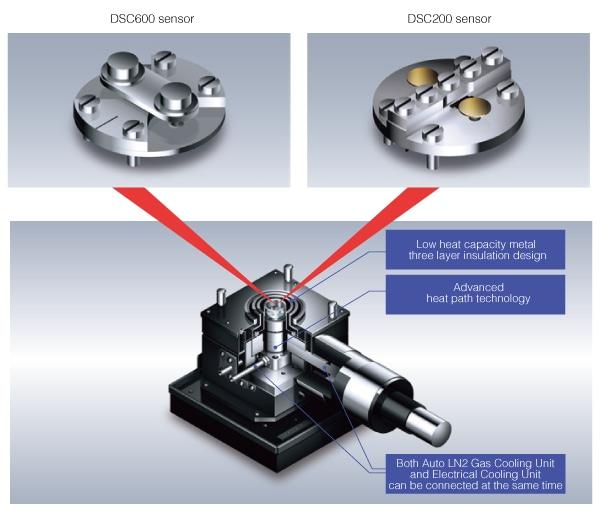

Both NEXTA DSC600 and DSC200 use an advanced heat-flow design in the sensor. This allows the heat from the heat sink transferred evenly to the sample and the reference, resulting in the high baseline stability. Together with a furnace built with a low-heat-capacity three-layered insulation design, this allows the NEXTA DSC achieves world-class baseline repeatability and stability.

World-class sensitivity

The NEXTA DSC600 has a proprietary thermopile-type DSC sensor. By using differential scanning calorimetry (DSC signal) temperature sensor thermocouples connected in series and multiplexed, the NEXTA DSCs achieve a high sensitivity of 0.1 µW or lower, enabling measurement of even smaller samples.

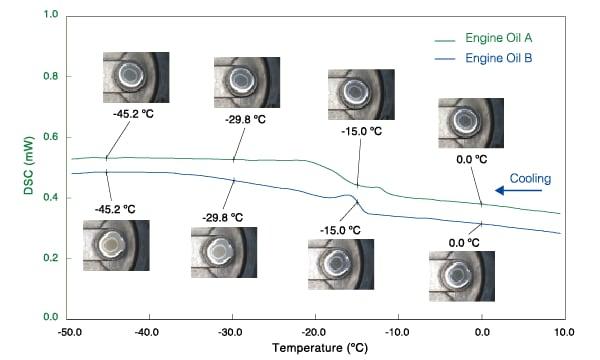

Wider temperature range for Real View® DSC

The Real View Sample Observation Unit has a built-in two-megapixel high-resolution camera that supports visual observation of the sample. The viewport (observation window) has a heating mechanism that extends the

measurement range from the conventionally observable range of room temperature and above down to the low temperature of -50°C. This enables the user to observe processes such as the crystallization and the glass transition, for example, of samples at low temperatures. This offers a unique capability for understanding material behavior.

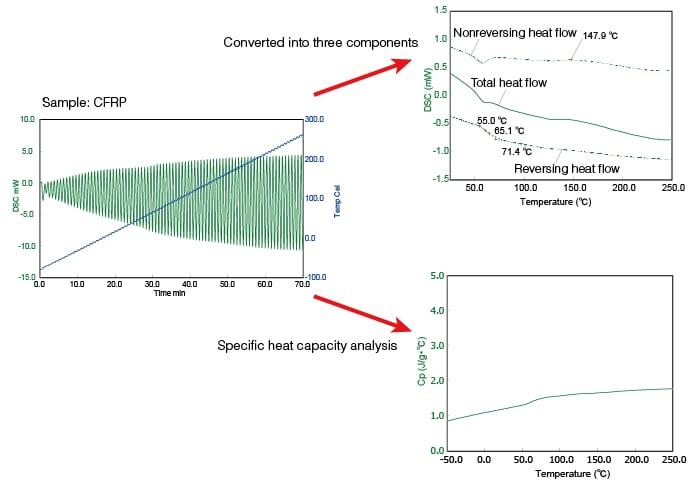

Specific heat capacity determination by temperature modulated DSC method

The reversing heat flow (which shows glass transition and melting) and non-reversing heat flow (which shows enthalpy relaxation, curing, evaporation, decomposition, etc) are obtained from a modulated DSC measurement. This is useful when these transitions or reactions overlap or stress relief obscures a transition. The modulated DSC method can also be used for determining the specific heat capacity (Cp), which simplifies measuring Cp.

-

DSC600 DSC200 Measurement principle Heat Flux Temperature Range -150℃~725℃ DSC dynamice range ±100mW ±200mW RMS noise / Sensitivity 0.05μW/0.1μW 0.1μW/0.2μW Calorimetric precision ±0.05%

* Calculated from the standard deviation (1σ/average value in In 10 consecutive measurement)

Baseline repeatability ±5μW

* Electrical Cooling Unit: -50~300˚C, 10˚C/minProgrammable rate 0.01℃~100℃/min

Purge gas

Air, Inert gas Purge gas control Mass flow controller, 2 lines Auto Sampler * Max.50 samples Electrical Cooling Unit * -80℃~500℃ Auto LN2 Gas Cooling Unit * -150℃~725℃ Auto Air Cooling Unit Ambient ~725℃ *Optional

-

▶ Polymer Materials

▶ Metal Materials

▶ Ceramic Materials

▶ Electronics and Optoelectronics Materials

▶ Nanomaterials

▶ Biomedical and Pharmaceutical Materials

▶ Others

Other applications, such as in food, commonly analyzed properties include:

(1) Phase Transition

(2) Glass Transition Temperature (Tg)

(3) Melting Point (Tm)

(4) Cold Crystallization Temperature

(5) Cooling Crystallization Temperature

(6) Crystallinity

(7) Reaction Kinetics

(8) Enthalpy of Fusion (△H)

(9) Heat of Reaction (△H)